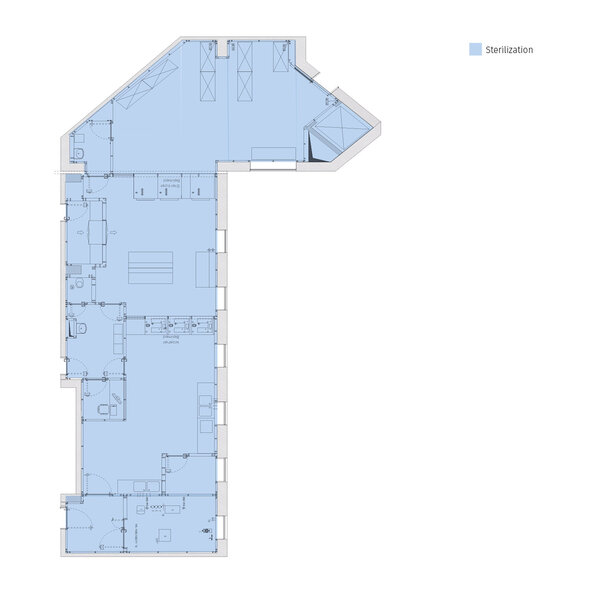

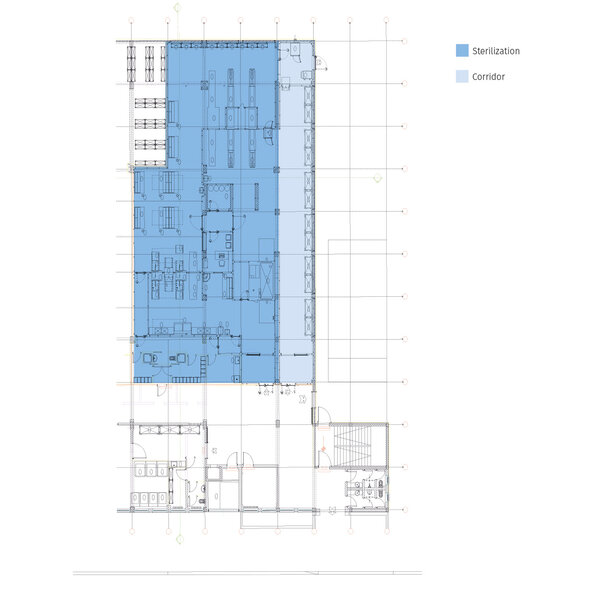

When planning an AEMP, efficient workflows, clear routing, and hygienic separation must be taken into account. The room concept should support logical material flows – from “unclean” to “clean” – and consistently prevent cross-contamination. An AEMP area is divided into three functional zones: the contaminated area (receipt and cleaning), the disinfected area (inspection, maintenance, packaging), and the sterile area (sterilization, release, and storage). This separation is not only necessary for hygiene reasons, but also makes sense from a work organization perspective, as it defines clear responsibilities and safety levels.

Another important aspect is the flexibility of the room design. Space and equipment requirements can change over the course of the service life – for example, due to increasing case numbers, new generations of instruments, or changes in reprocessing procedures. The variable, modular room solution from the HT Group offers significant advantages here and enables sustainable use over many years.

With the HT modular systems, all room concepts in the AEMP can be fulfilled and room solutions with hygienically flawless structural separation can be realized with the integration of loading and unloading units, disinfection devices, sterilizers, and sterile storage rooms.